Plasticizers are additives used in the manufacturing of plastics to modify their properties, such as flexibility, durability, and workability. They are incorporated into polymer formulations to improve processability, reduce brittleness, enhance elongation, and lower the glass transition temperature of the plastic material. Plasticizers are widely used in various industries and applications, including:

1. PVC (Polyvinyl Chloride) Products:

– PVC is one of the most common polymers used in conjunction with plasticizers. Plasticizers help soften rigid PVC formulations, making them more flexible and versatile for applications such as:

– Flexible PVC films and sheets for packaging materials, cling films, and inflatable products.

– PVC cables and wires for insulation and sheathing.

– PVC flooring, wall coverings, and synthetic leather for upholstery and automotive interiors.

– PVC pipes and fittings for plumbing and construction.

2. Plasticized Polyethylene (PE) and Polypropylene (PP):

– Plasticizers can be added to polyethylene and polypropylene to improve their flexibility and processability. Plasticized PE and PP are used in various applications, including:

– Flexible packaging films and bags for food packaging, industrial packaging, and agricultural applications.

– Flexible containers, bottles, and squeeze tubes for cosmetics, personal care products, and household chemicals.

– Flexible tubing and hoses for medical, pharmaceutical, and laboratory applications.

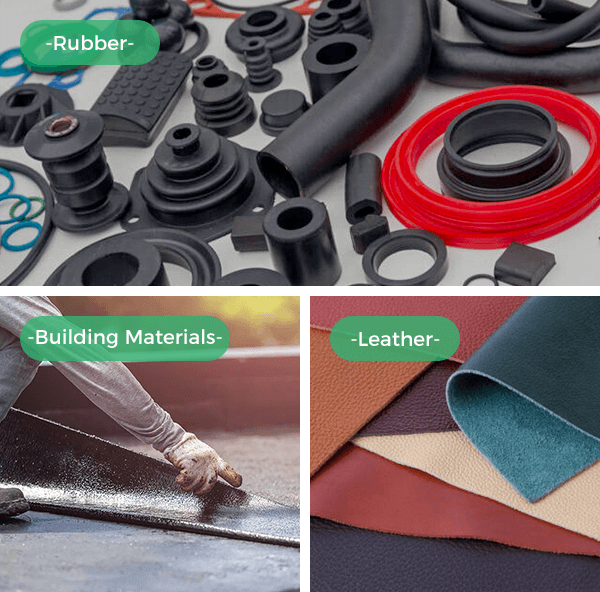

3. Rubber and Elastomer Products:

– Plasticizers are commonly used in rubber and elastomer formulations to improve their flexibility, resilience, and moldability. Plasticized rubbers and elastomers are used in applications such as:

– Rubber gaskets, seals, and O-rings for automotive, aerospace, and industrial applications.

– Rubber hoses, conveyor belts, and vibration dampers for machinery and equipment.

– Elastomeric coatings, adhesives, and sealants for construction and waterproofing.

4. Polyurethane (PU) Foams and Coatings:

– Plasticizers are added to polyurethane foams and coatings to enhance their flexibility, elasticity, and impact resistance. Plasticized PU foams and coatings are used in applications such as:

– Flexible foam cushions and mattresses for furniture, bedding, and automotive seating.

– Flexible foam insulation panels and pipes for thermal and acoustic insulation.

– Flexible PU coatings for textiles, fabrics, and flexible substrates.

5. Adhesives, Sealants, and Coatings:

– Plasticizers are used in the formulation of adhesives, sealants, and coatings to improve their tackiness, flexibility, and adhesion properties. Plasticized adhesives, sealants, and coatings are used in applications such as:

– Pressure-sensitive adhesives for tapes, labels, and decals.

– Sealants and caulks for construction, automotive, and industrial sealing applications.

– Coatings and finishes for paints, varnishes, and protective coatings.

Overall, plasticizers play a crucial role in enhancing the performance, versatility, and applicability of plastic materials across a wide range of industries and applications. Their ability to modify the properties of polymers makes them indispensable additives in the formulation of various plastic and rubber products.